Civil

The

requirements for Model Railroad Engineer - Civil may look long and

complicated, but they really are not. The reason that they are so long

is to offer you more options for meeting the requirements.

Remember - don't read more into the requirements than is there.

To qualify for the Model

Railroad Engineer - Civil certificate:

1.

Prepare

one original scale drawing of a model railroad track plan, identifying overall

size, scale, track elevations, curve radii, and turnout sizes.

You should also consider the requirements for Model Railroad Engineer -

Electrical, and Chief Dispatcher when planning your layout - it is much easier

to include the requirements in the planning stage than to go back and add them

later.

This plan must include:

1.

Adequate

terminal facilities for handling freight and/or passenger cars

2.

Adequate

terminal facilities for storage and service of motive power

3.

A

minimum of one mainline passing siding

4.

Four

switching locations, not counting yards, interchanges, wyes, and reversing

loops

5.

Provision

for turning motive power (except for switchbacks, trolley lines, etc.)

6.

Provision

for simultaneous operation of at least two mainline trains in either direction.

Here you may use the same plan as in Model Railroad Engineer - Electrical

2.

Construct

and demonstrate, the satisfactory operation of a completed section of the model

railroad and track work described in #1. Containing at least 25 linear feet in

Z, N, or TT scale, or 50 linear feet in HO or S scale, or seventy five linear

feet in O scale, or 100 linear feet in G or #1 scale, or other scales in

proportional relationship to HO scale, with appropriate ballast, drainage

facilities, and roadbed profile, which may contain spurs, yards, etc.

The

track work must have examples of six of the following features:

- Passing Siding

- Spur

- Crossover

- Reversing Loop

- Wye

- Simple Ladder

- Compound Ladder

- Turntable

- Transfer Table

- Super Elevation

- Simple Overhead Wire - A single

overhead wire (such as on a trolley system)

- Compound Overhead

Wire (catenary)

- Scale Track

- Cog Railway Track

- Coal Dump Track

- Ash Pit

- Service Pit Track

- Grade Elevation

- Other

__________________ This has been witnessed on my home layout

3.

Construct

for Merit Judging, scratch built scale models of any three of the following,

and demonstrate their satisfactory operation:

- Turnout (this is probably the easiest to build, lots of information in magazines etc.)

- Crossover

- Double Crossover

- Single Slip Switch

- Double Slip Switch

- Crossing (probably the toughest to build. Lots of soldering to hold everything together)

- Gauntlet Track (I always wanted to build one)

- Gauntlet Turnout

- Dual Gauge Turnout

- Gauge Separation

Turnout

- Double Junction

Turnout

- Three-Way Turnout

- Spring Switch

- Operating Switch in

Overhead Wire

- Other ___________

Commercial

frogs are not permitted to be used in any of these items. These models may be

built and demonstrated as part of the layout or separately.

I had a bag of switch ties left, so I needed to shorten the ties with my NWSL chopper.

Previously I had built a jig to space the ties correctly

Then I pressed a strip of scotch tape on the ties and lifted them out of the jig. I pressed the strip ties into a bed of white glue applied on a piece of plywood.

Before laying track I ballasted the ties. This leaves no loose ballast on top of the ties.

I started with the outside rails until they touched at the frog.

NMRA standards gauge and some Micro Engineering track gauges come in very handy to build and check handlaid track.

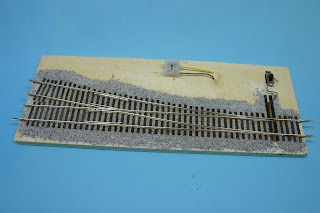

The finished turnout

Same procedure for the crossing

The diamond is the trickiest part. To avoid shorts, I had to cut many gaps. The best way is to solder the guard rails to the outside rails and then cut the caps. Spikes alone cannot hold everything together reliably.

This is the centerpiece of my gauntlet track.

The jig for spacing the ties.

The ties for the turnout.

I used a slide switch connected to throw the turnout. The elctrical contacts power the frog

I used a DPDT switch to power either route of the crossing

4.

You

must win a Merit Award (at least 87.5 points) with the items in section 3

above.

0. Attachment to the SOQ showing the track

plan required in Section 1 above. The attachment should include:

- Identification of all scratch built

features

- All commercial

components used

- Materials used in building the model

1.

Description

of the track work features, methods of construction and identification of

commercial components used in Section 3.

2. Verification

of the Merit Awards

3.

Witness

Certification showing that each of the above models meets all applicable NMRA

standards.

Here is my description of the 3 track work features:

MODEL RAILROAD ENGINEER – CIVIL

Track Work models for Merit

Award Judging

I’ve chosen

to scratch build the following models of railroad track work:

-

turnout

(point)

-

crossing

(90°)

-

gauntlet

track

CONSTRUCTION

To start I

constructed a tie spacing jig to lay out the ties in an even spacing. Then I’ve

cut the ties to their appropriate length using a NWSL Chopper.

I placed

the ties in the template. Then I glued a strip of Scotch Tape on top of the

ties to lift the whole length out of the template.

On a small

piece of plywood I spread a layer of white glue and set the ties into the glue.

Then I pressed the ties down until the glue had hardened. Then I pulled the

tape off. I used a mix of stained and unstained ties. (see template and

pictures)

When the

glue had set I ballasted the ties using a mix of Woodland Scenics Grey Blend

Ballast. When the ballast was evenly spread between the ties I soaked the

roadbed with a mix of distilled water and 70% isopropyl alcohol. Then I applied

a 7:1 mix of matte medium and distilled water and also added a few drops of

isopropyl alcohol.

When the

roadbed had completely dried overnight I started to lay the rails following a

construction article from Tony Koester published in Model Railroader and in the

Kalmbach book “Trackside and Line side Details”.

I nailed

every piece of rail down with track spikes on both sides on every tie.

DETAIL

I used

individual rails from PECO and nailed the rails to every tie from both sides. I

did the same for the guard rails.

CONFORMITY

The

turnouts and crossings are built following prototype practices from the

construction article.

FINISH

AND LETTERING

I ballasted

the ties prior to nailing the rails. By this way there is no ballast on the

ties or stuck to the sides of the rails. Every piece of rail is nailed on both

sides and on every tie. Nothing is glued. I soldered the switch rod to the

points of the closure rails and the point of the frog. The guard and wing rails

were also soldered to the rails to give them more strength.

The

different pieces of track work have to be wired differently.

The turnout

was wired at the point of the switch. The frog was polarized with one wire and

connected to an SPDT switch to feed it with the correct polarity.

The gauntlet

track was wired according to the following drawing,with the 2 rails between the

frogs connected to an SPDT switch to route the correct polarity. Gauntlet

tracks can only be travelled by one train at a time, while the other train is

waiting in a siding. The 2 tracks between the frogs may be positive or negative

depending on which track will be used.

The crossing

was isolated by cutting the four tracks in the diamond and connecting it to a

DPDT switch to route the correct polarities as per the following drawing.

Finally I

weathered the rails using Floquil weathering sticks.

SCRATCHBUILDING

I’ve

scratch built all the track work, using individual rail length, stained and

unstained ties and spikes. The frogs are soldered and the switch rod is soldered

to a PC-board tie. I also used commercial rail joiners and insulating joiners.

Parts

List

PECO IL-3 Individual Rail code 75

SL-110 Rail Joiners

SL-111 Insulating Rail Joiners

KAPPLER KP060 Switch Ties

MICRO

ENGINEERING 36-101 Regular Length HO Scale Ties

Track

gages

XURON 82839 Spike Insertion Pliers

84365 Rail Cutting Pliers

WOODLAND

SCENICS Ballast

Grey Blend

NMRA HO

Gauge

Needle

Files

Soldering

Iron, Solder and flux

PC-Board

tie